DCL provides advanced emissions control technologies tailored specifically for the demanding requirements of power generation operations. Our reliable, industry-leading solutions ensure regulatory compliance, enhance operational efficiency, and support environmental sustainability. Optimized for diverse fuel types including diesel, biogas, natural gas, and syngas, our products deliver consistent performance. They are trusted across North America and key European markets such as Italy, Germany, France, the UK, and the Netherlands.

DCL offers customized solutions through complete vertical integration. Our in-house capabilities in catalyst formulation and precision metal fabrication allow us to deliver unmatched product quality, customization, and optimization tailored to your specific operational requirements.

Our advanced engineering team utilizes sophisticated Computational Fluid Dynamics (CFD) modeling, supported by state-of-the-art engine testing facilities. This comprehensive approach ensures product reliability and validated performance under real-world conditions.

DCL is committed to certified quality and excellence. We operate under an ISO 9001:2015 Quality Management System, manage ASME-certified manufacturing facilities, and maintain extensive global emissions certifications. Our proven track record and strategic partnerships with leading OEMs worldwide underscore our credibility and leadership in emissions control.

Recognizing the importance of regional compliance and support, DCL maintains a deep understanding of regional emissions regulations and an extensive global support network. Our localized approach provides solutions, fully optimized to meet specific compliance needs, ensuring a seamless experience and operational confidence for our clients.

In North America, DCL provides emissions control solutions engineered to comply with stringent U.S. federal and state emissions standards, addressing pollutants such as NOx, CO, hydrocarbons, and particulate matter. Our “Made in the USA” products also support Buy America and IRA provisions.

In Europe, DCL designs and delivers emissions solutions tailored specifically for stringent EU standards. Our local expertise ensures effective navigation of regulatory frameworks, meeting the compliance needs of key European markets.

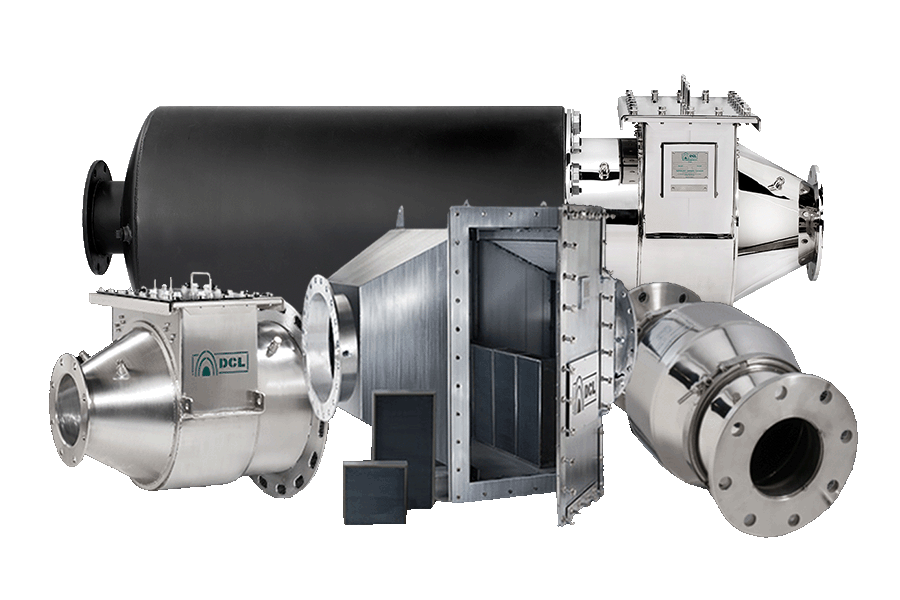

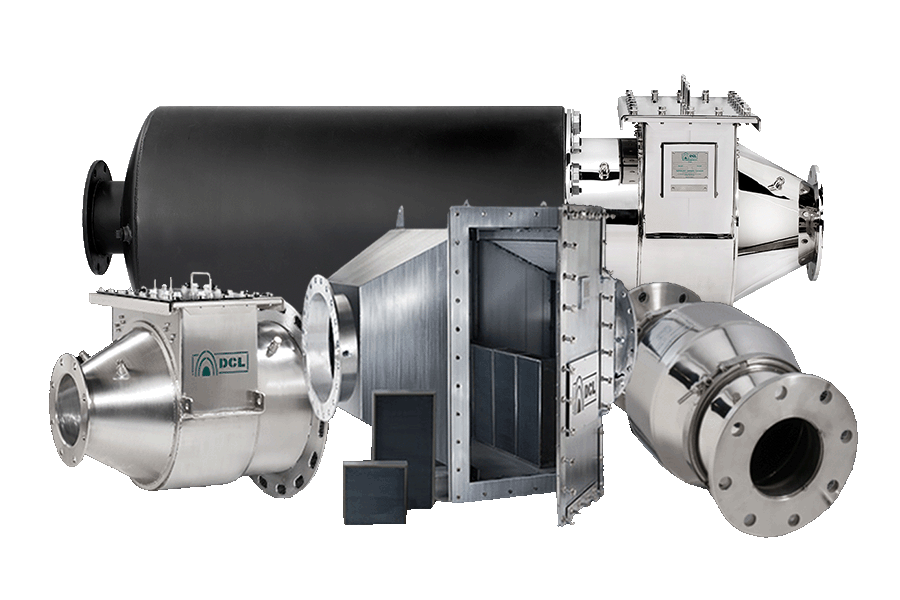

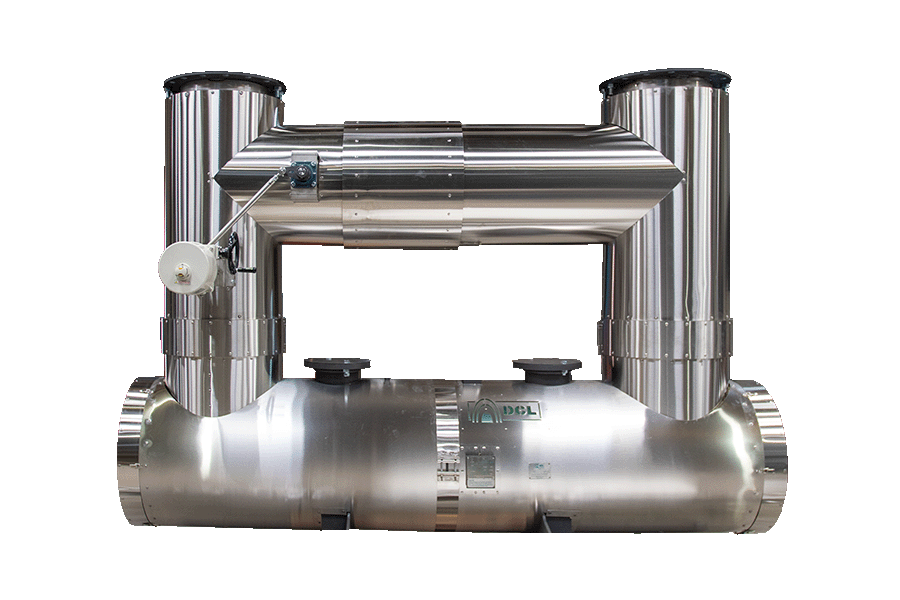

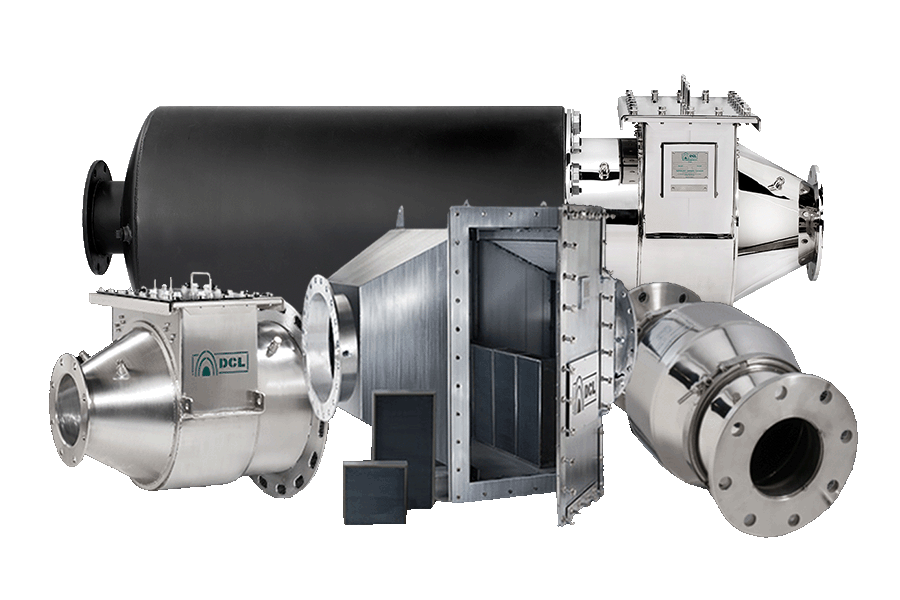

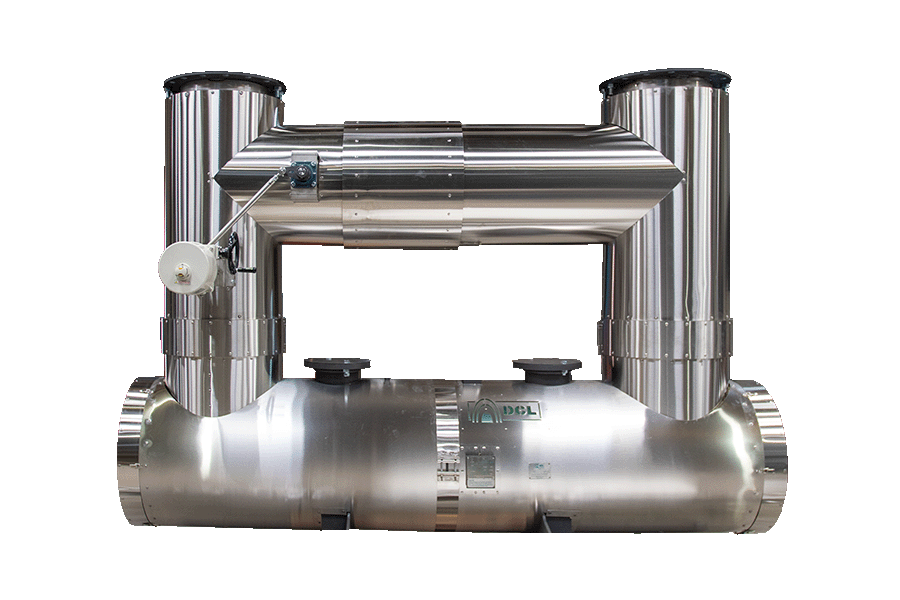

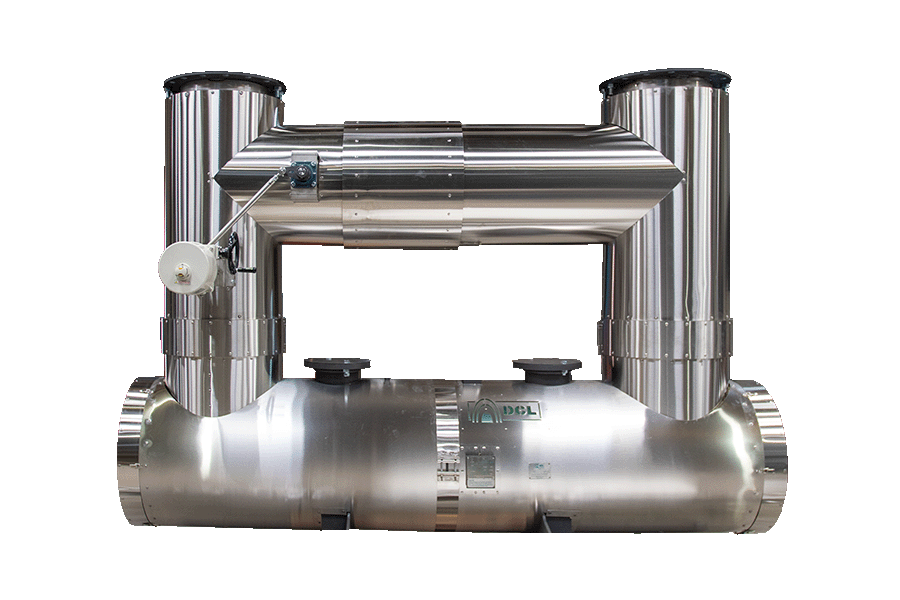

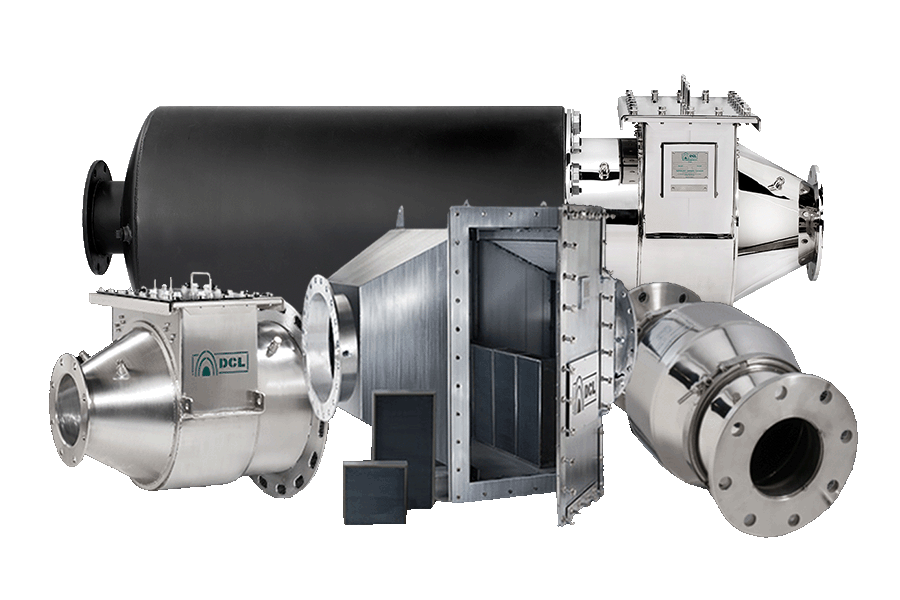

DCL provides a diverse range of products including catalytic converters and silencers such as the MINE-X®, Mini Quick-Lid, Quick-Lid®, RC, and RCB systems, which can integrate with heat recovery and noise attenuation systems.

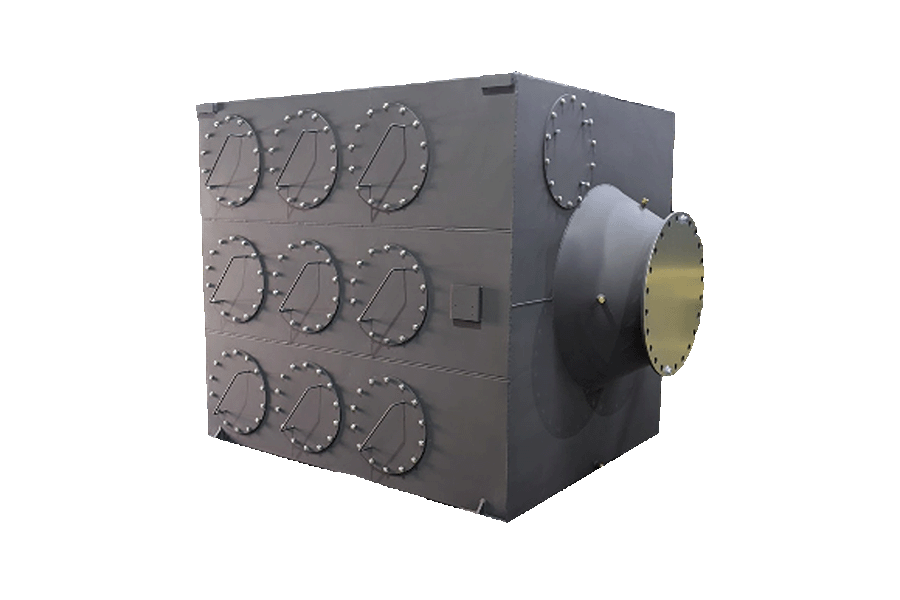

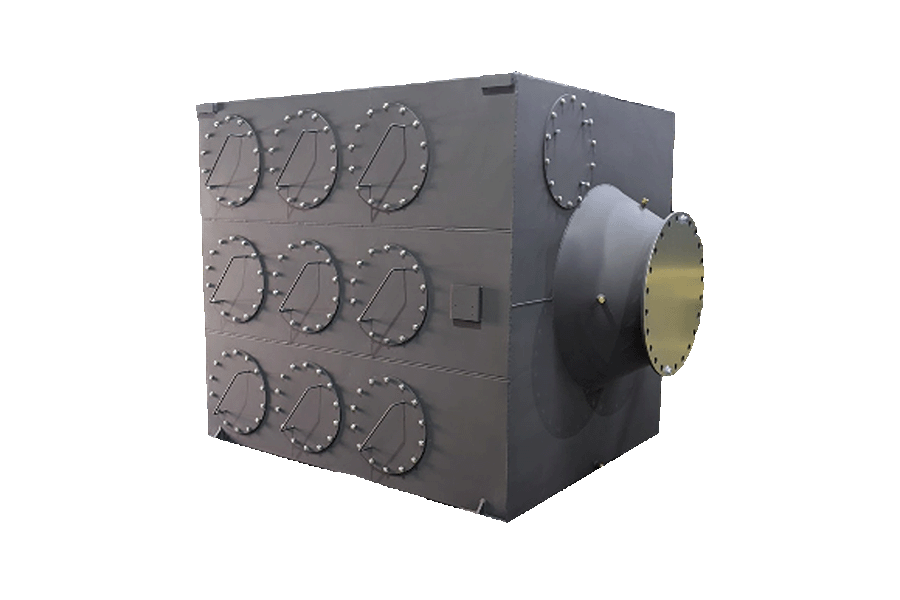

Our diesel particulate filters (DPFs) include cordierite and silicon carbide options, both CARB-verified and standard configurations, offered in single or multi-unit housings for versatile installation.

We offer high-quality heat exchangers, including fin-coil and shell-and-tube designs, available in standalone or integrated configurations, compatible with various operating fluids such as water, glycol, or thermal fluids.

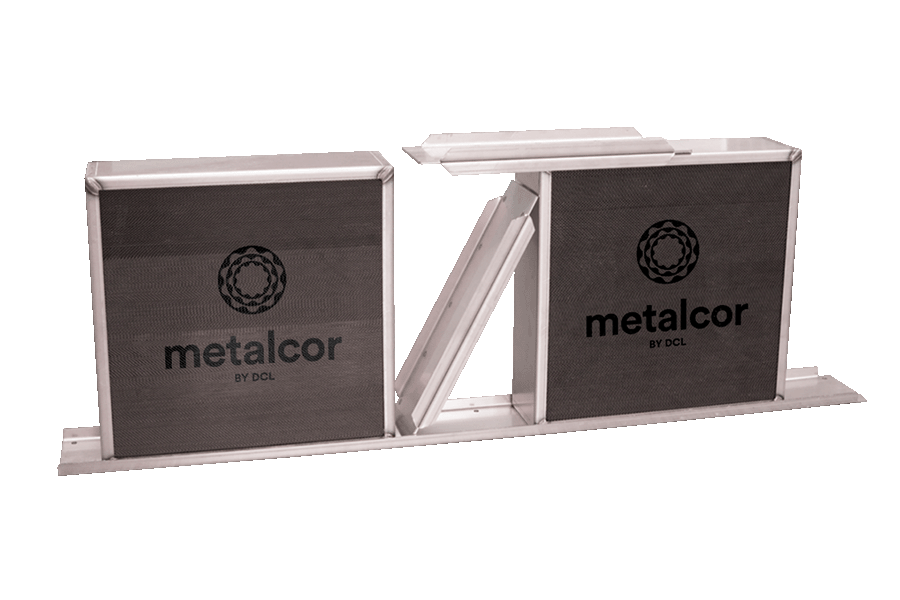

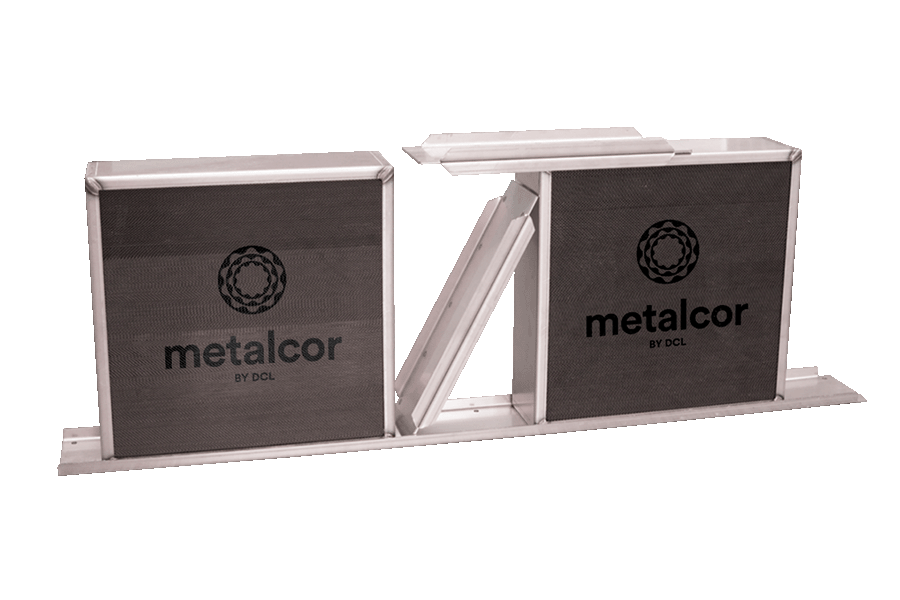

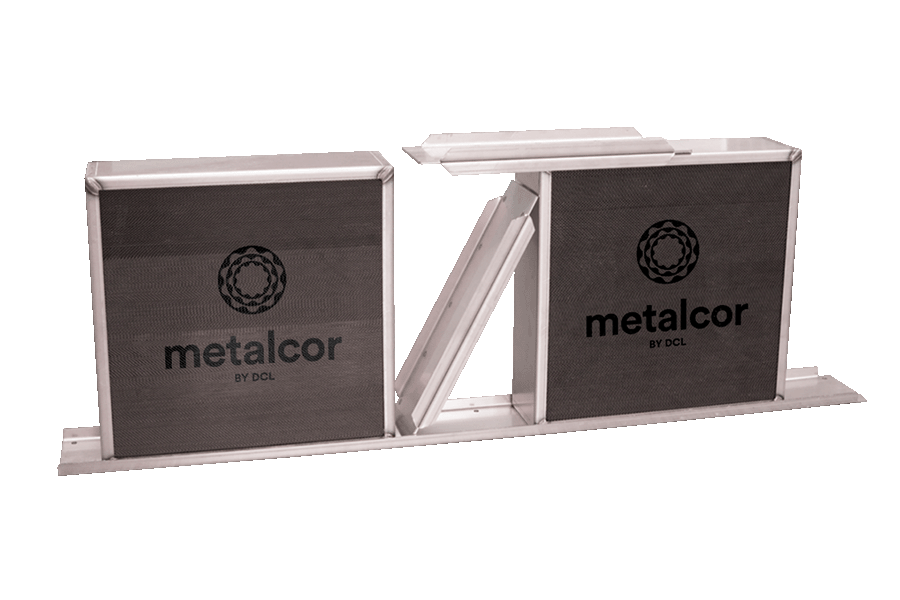

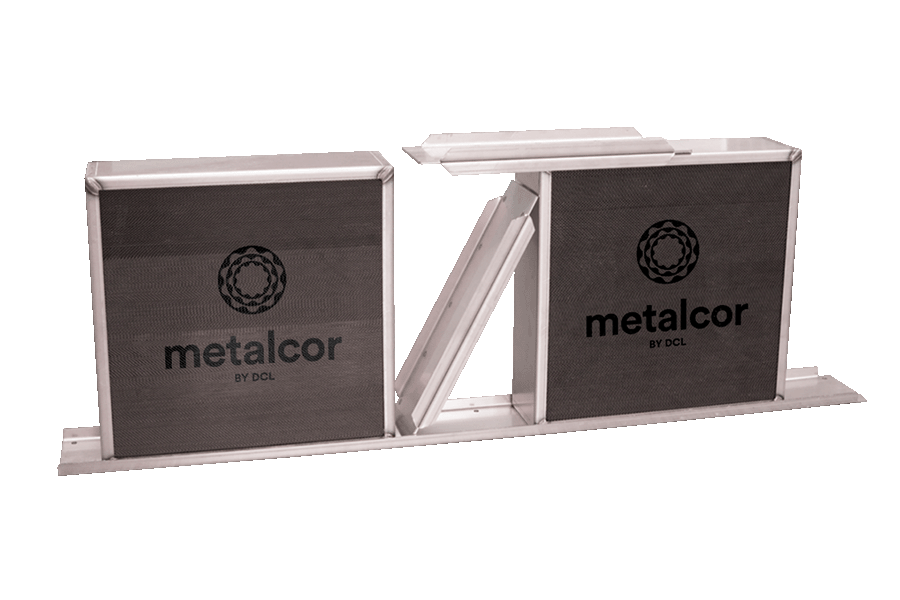

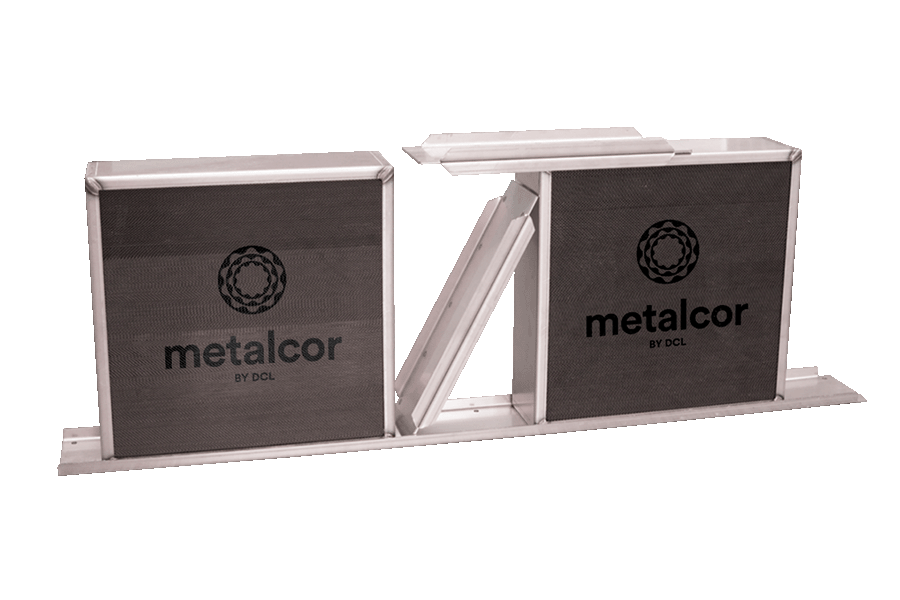

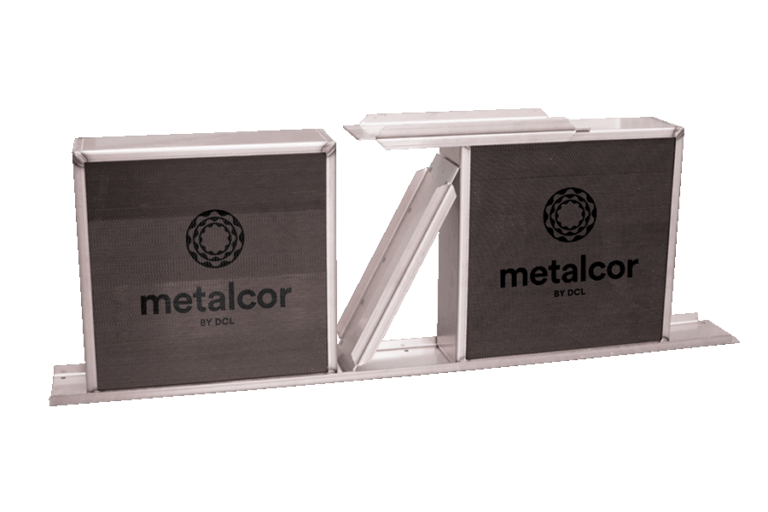

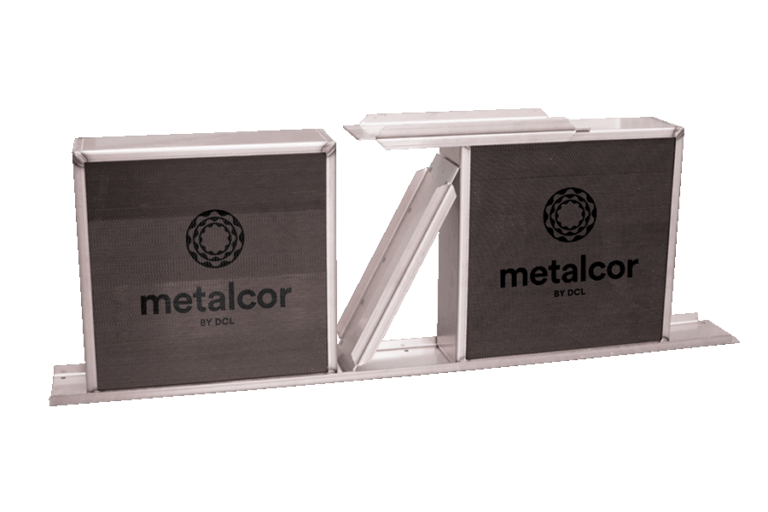

DCL’s Metalcor® catalyst elements deliver superior performance for oxidation, SCR, or NSCR applications, with customizable shapes and sizes, ensuring exceptional efficiency and long-term durability.

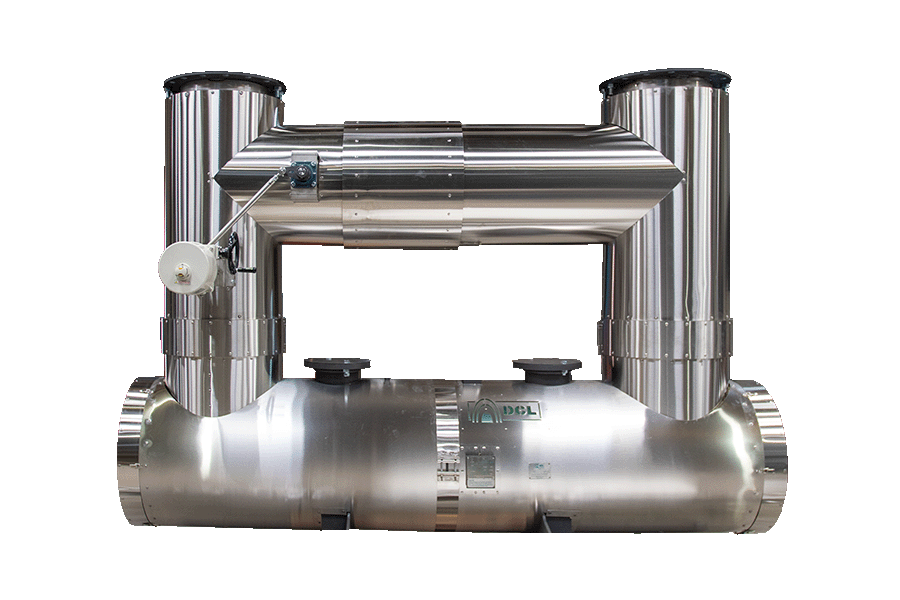

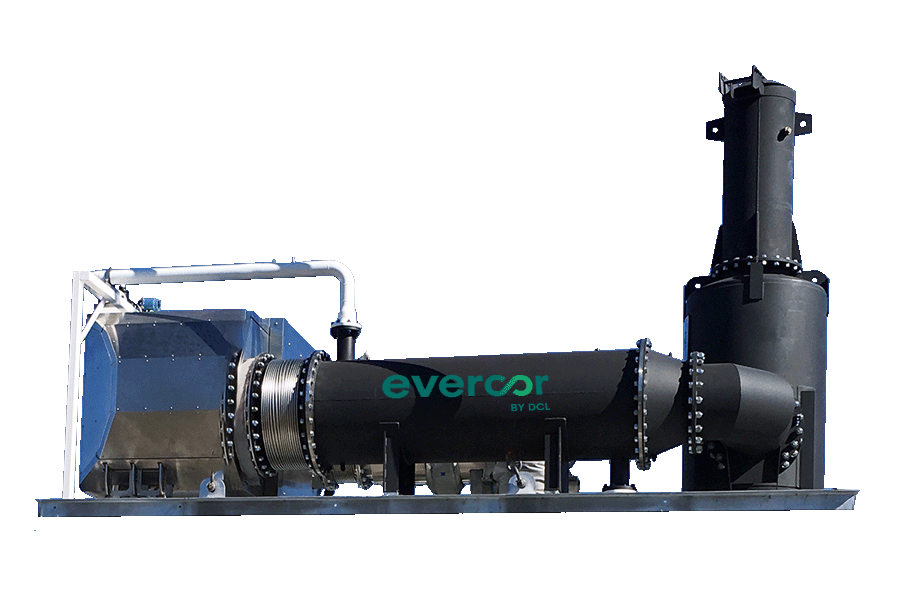

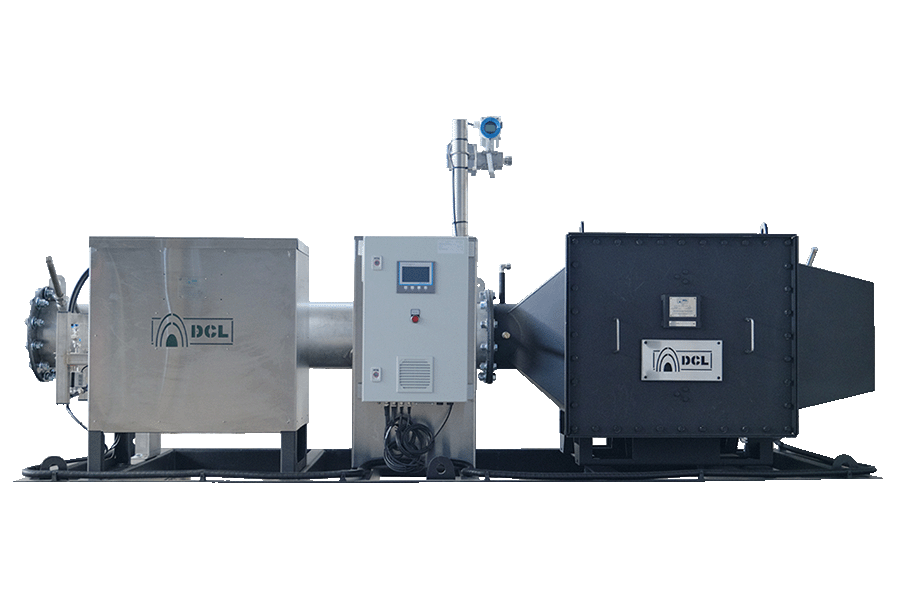

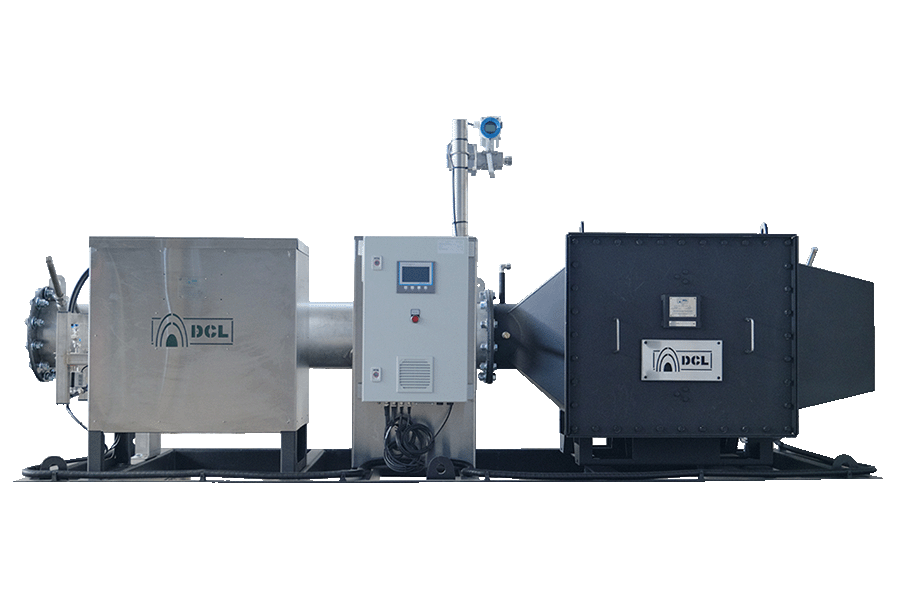

Our advanced SCR systems are provided in collaboration with our partner company AERINOX Inc. These systems combine superior catalyst and housing technologies with innovative controls and precise injection systems to ensure peak performance.

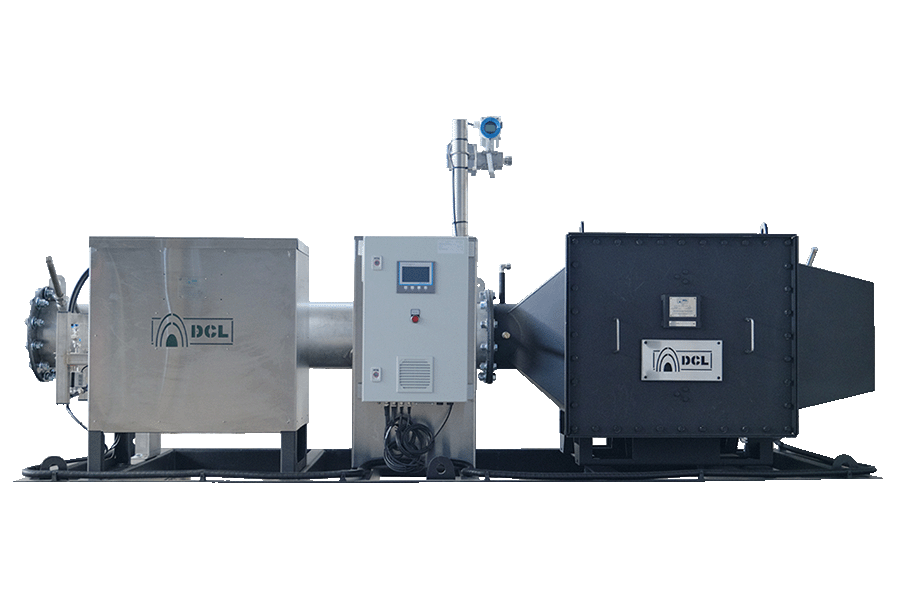

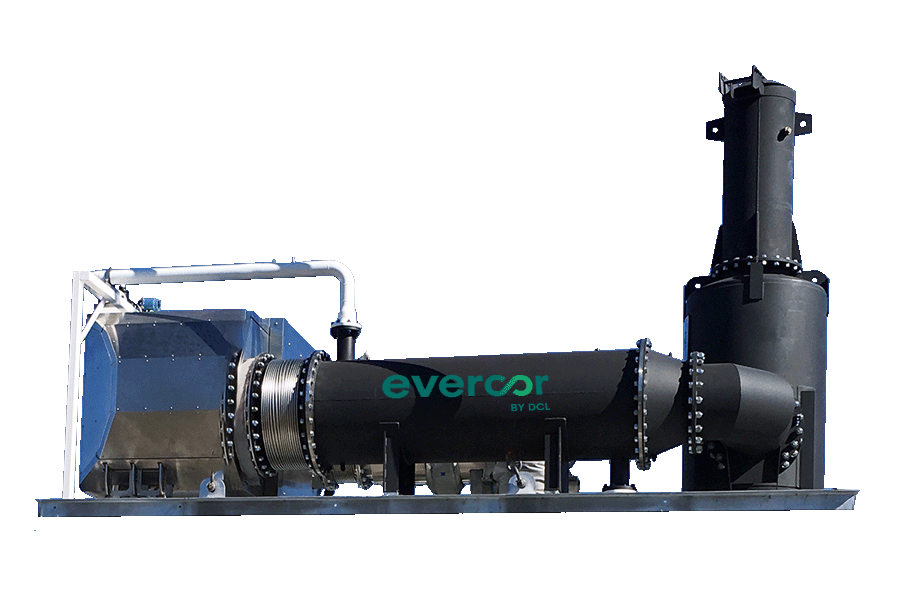

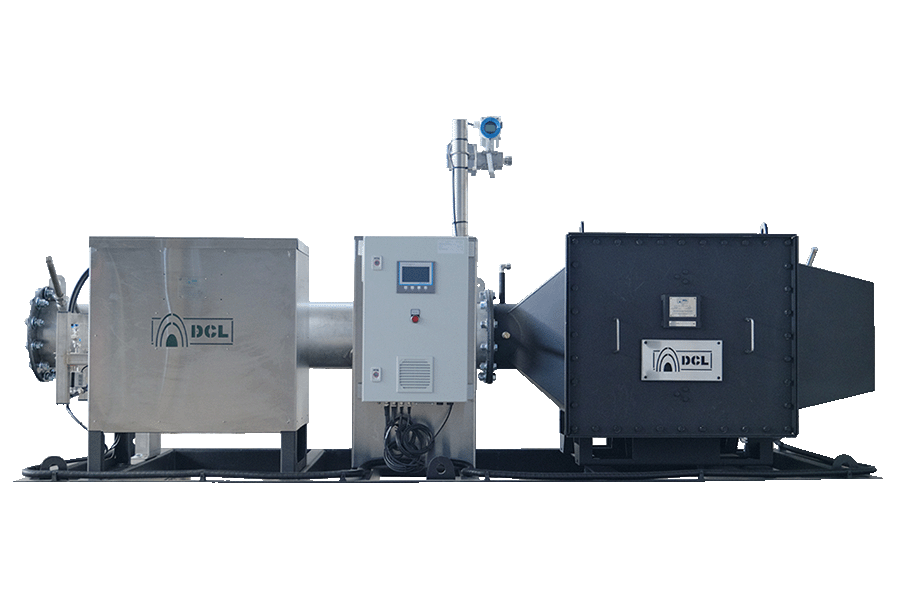

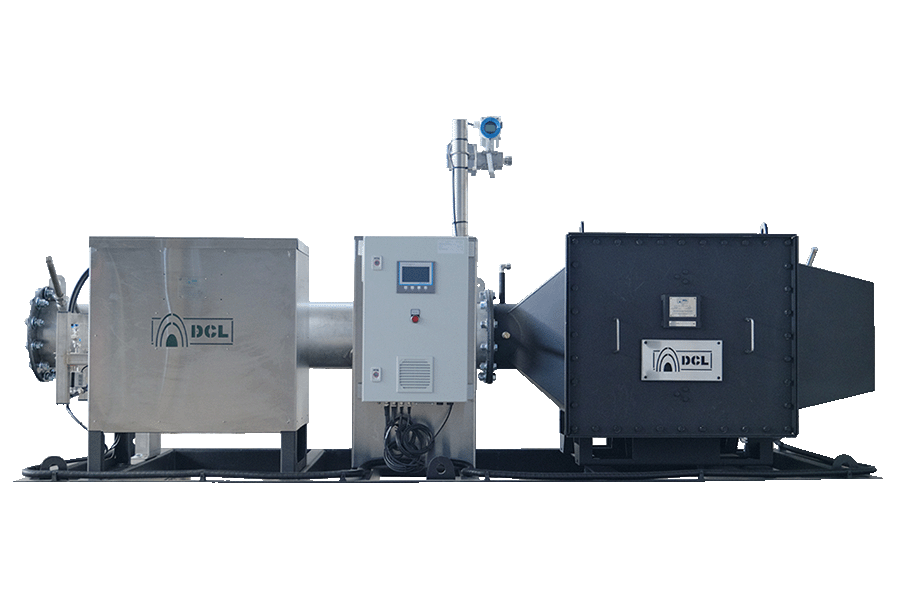

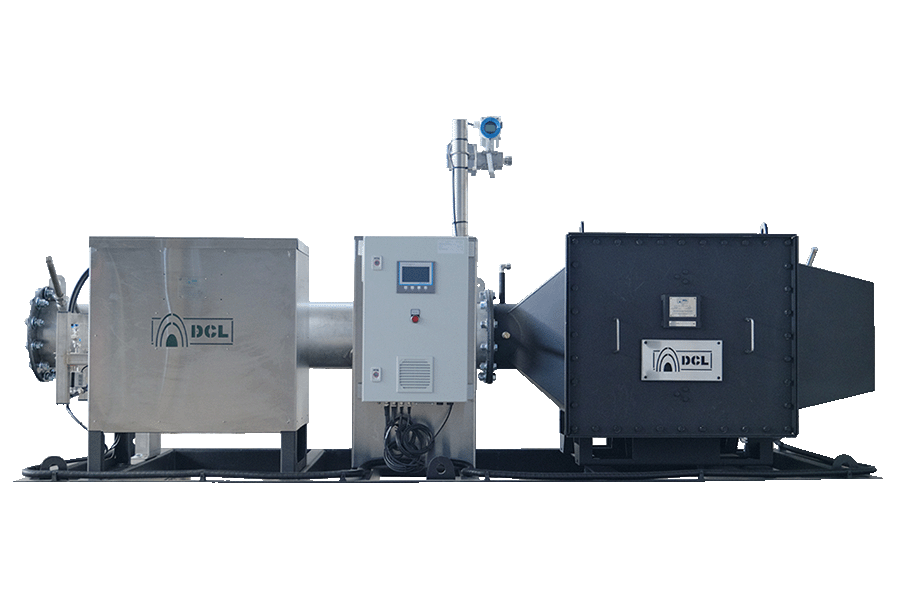

Additionally, our system skid solutions offer custom-engineered, plug-and-play convenience, integrating emissions control, heat recovery, and noise attenuation in turnkey packages equipped with pre-wired conduit, sensors, and controls for simplified installation.

From catalyst formulation to custom metalworking, DCL controls all manufacturing aspects of its products resulting in consistent high quality and a level of customization and optimization for our customer unmatched in the industry.

DCL employs the latest modeling software with finite element analysis and computational fluid dynamics as well as our state of the art engine test cells to develop our products.

Continuous improvement and excellence is standard at DCL with our ISO 9001:2015 QMS certification, two ASME certified manufacturing facilities and several dozen global emissions certifications with national and regional governmental entities. In addition, partnerships with numerous OEM equipment manufacturers for certified engine emissions products further cement DCL as the market leader.

Understanding that power generation needs and regulations vary significantly across regions, DCL boasts an extensive global network offering after-sales support and deep knowledge of local emission standards. This regional advantage ensures that our solutions are not only technically sound but also fully compliant and optimized for local market demands, providing a seamless experience for our clients worldwide. Our global presence and regional expertise position us as the ideal partner for power generation entities looking to navigate the complexities of modern energy production and environmental stewardship.

From data centers to distributed generation, in the United States, power generation is subject to numerous federal and state regulations to reduce NOx, CO, Hydrocarbons and Particulate Matter. DCL can help you navigate these regulations and develop solutions with our diverse offerings and support the Buy America and IRA provisions with our Made in the USA products. DCL has technologies optimized for any fuel type from biogas to diesel to syngas. If you operate in Canada, MSAPR regulations apply and DCL can also provide assistance.

DCL offers five systems for catalytic converters; MINE-X®, Mini Quick-Lid, Quick-Lid®, RC and RCB. All can be close coupled with heat recovery or noise attenuation systems.

DCL offers cordierite and silicon carbide CARB verified and non CARB diesel particulate filters that can be packaged singly or in multiple housing arrangements.

DCL offers fin coil and shell and tube heat exchanger systems as stand alone or close coupled with emission control or noise abatement systems and designed to operate with water, water glycol or thermal fluids.

DCL offers best in class catalyst elements for oxidation, SCR or NSCR requirements in any shape or size.

DCL partners with our sister company AeriNOx Inc. for our SCR system offering which combines our catalyst and housing technology with cutting edge controls and injection systems from AeriNOx.

DCL offers custom skid mounted systems that can include emissions control, heat recovery and noise attenuation and are plug and play with all conduit, sensors and wiring ready to connect.

Italy’s approach to power generation emphasizes sustainability and compliance with European Union directives, focusing on renewable energy integration and emissions reduction. The country adheres to EU regulations, including stringent emissions standards for pollutants such as NOx, SOx, CO, and particulate matter, to mitigate environmental impact and promote public health.

The Italian power sector is characterized by a significant shift towards renewable energy sources, such as solar and wind, complemented by traditional power generation methods. To support this transition and ensure regulatory compliance, power generation facilities in Italy incorporate advanced emission control technologies. DCL’s offerings, including Metalcor® oxidation catalysts and heat exchangers, are pivotal in this context. They enhance energy efficiency and reduce emissions, facilitating Italy’s progress towards its ambitious environmental and energy goals.

These catalysts are specifically designed for the high-demand environments of power generation, effectively reducing emissions of CO, VOCs, and other pollutants to comply with strict environmental standards.

Our converters and silencers are engineered to address both emission control and noise reduction, providing a dual-purpose solution that supports operational excellence and community goodwill.

For NOx reduction, DCL’s SCR systems offer a reliable solution to meet and exceed regulatory requirements, ensuring power plants can achieve lower emissions without compromising on efficiency.

Germany’s power generation sector operates under stringent environmental standards, primarily governed by the 44. BImSchV, which sets rigorous limits on emissions such as NOx, SOx, CO, and particulate matter. This legislation reflects Germany’s commitment to environmental protection and its pioneering role in the Energiewende, the transition towards renewable energy and reduced carbon emissions. The focus on sustainability mandates the integration of advanced emission control technologies to comply with these strict regulations.

To align with these standards, power generation systems in Germany extensively utilize high-efficiency Combined Heat and Power (CHP) units running on natural gas or biogas, and are increasingly integrated with renewable energy, including CHP hydrogen engines. DCL’s emission control solutions, including Metalcor® oxidation catalysts and heat exchangers, support this integration by enhancing efficiency and reducing the environmental impact of both conventional and renewable-based power systems. Our products are designed to meet the specific needs of the German market, ensuring compliance with current regulations and contributing to the country’s energy transition goals.

These catalysts are specifically designed for the high-demand environments of power generation, effectively reducing emissions of CO, VOCs, and other pollutants to comply with strict environmental standards.

DCL's heat exchangers are designed to recover waste heat from exhaust gases in power generation, improving energy efficiency and reducing carbon footprints.

For NOx reduction, DCL’s SCR systems offer a reliable solution to meet and exceed regulatory requirements, ensuring power plants can achieve lower emissions without compromising on efficiency.

In the Netherlands, cogeneration systems, particularly in greenhouse operations, play a crucial role in the country’s innovative and sustainable approach to power generation. These systems efficiently produce heat and electricity simultaneously, supporting the Netherlands’ commitment to reducing greenhouse gas emissions and enhancing energy efficiency, especially in the agricultural sector.

The Dutch market’s focus on cogeneration aligns with European Union emissions standards, requiring sophisticated emission control technologies to meet stringent NOx, CO, and particulate matter limits. DCL’s expertise in emission control solutions, including Metalcor® oxidation catalysts and heat exchangers, is especially relevant here. Our products optimize the performance and environmental compliance of cogeneration systems, crucial for the extensive greenhouse industry in the Netherlands. By improving energy efficiency and reducing emissions, DCL supports the Netherlands’ greenhouse operators in achieving sustainable growth and contributing to the country’s environmental targets.

These catalysts are specifically designed for the high-demand environments of power generation, effectively reducing emissions of CO, VOCs, and other pollutants to comply with strict environmental standards.

DCL's heat exchangers are designed to recover waste heat from exhaust gases in power generation, improving energy efficiency and reducing carbon footprints.

For NOx reduction, DCL’s SCR systems offer a reliable solution to meet and exceed regulatory requirements, ensuring power plants can achieve lower emissions without compromising on efficiency.

France is actively advancing its decarbonization efforts within the power generation sector, with a growing focus on renewable energies and the reduction of carbon emissions across its energy systems. Adhering to stringent EU emissions regulations, France prioritizes technologies that enable significant reductions in NOx, CO, and particulate matter emissions. DCL’s Metalcor® oxidation catalysts and heat exchangers play a crucial role in this context, offering effective solutions for minimizing environmental impact while enhancing operational efficiency. Our emission control technologies support France’s commitment to sustainable energy production, aligning with the nation’s goals for a cleaner, greener future.

These catalysts are specifically designed for the high-demand environments of power generation, effectively reducing emissions of CO, VOCs, and other pollutants to comply with strict environmental standards.

For NOx reduction, DCL’s SCR systems offer a reliable solution to meet and exceed regulatory requirements, ensuring power plants can achieve lower emissions without compromising on efficiency.

The UK’s power generation sector is rapidly evolving, with a significant shift towards renewable energy and the phasing out of coal-fired power stations. This transition is guided by strict environmental regulations, including the UK’s ambitious targets for carbon reduction. DCL’s emission control technologies enable power generators in the UK to achieve compliance with these regulations, facilitating the country’s move towards cleaner, more sustainable energy production. Our products are key in optimizing the performance and environmental footprint of the UK’s diverse energy mix.

These catalysts are specifically designed for the high-demand environments of power generation, effectively reducing emissions of CO, VOCs, and other pollutants to comply with strict environmental standards.

Our converters and silencers are engineered to address both emission control and noise reduction, providing a dual-purpose solution that supports operational excellence and community goodwill.

When partnering with DCL, clients benefit from unparalleled expertise, robust support, and innovative emissions solutions specifically developed for the power generation industry. Our commitment to quality, regional compliance, and operational efficiency ensures our clients can confidently navigate the complexities of modern energy production.

Contact our specialists today for a personalized consultation to optimize your emissions control strategy.

Tell us about your project and it’s requirements and our team will respond to your request.