OXIDATION CATALYSTS FOR TURBINES

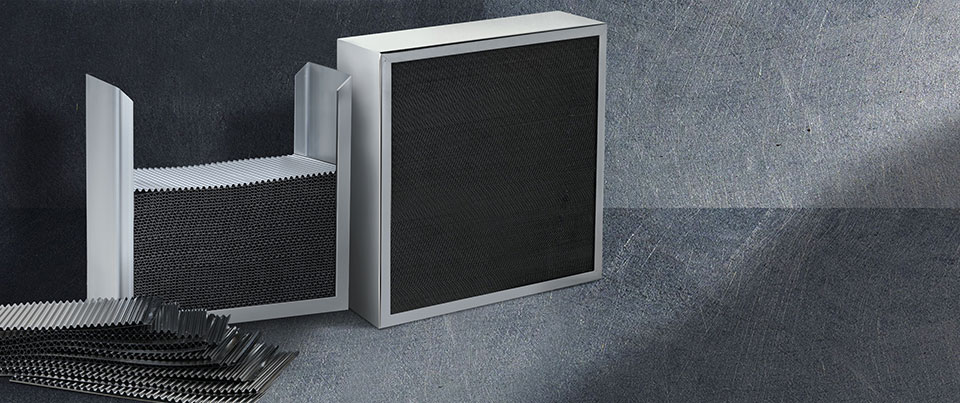

DCL's Metalcor® catalysts for turbines offer durable, cost effective

control of carbon monoxide (CO), volatile organic compounds (VOCs),

formaldehyde and other hazardous compounds. As a result of DCL's unique

manufacturing process and experience the Metalcor® catalyst element can

be produced in a variety of configurations, sizes, cell densities and

coatings. The thin-walled metallic catalyst substrate and platinum group

metal (PGM) coating is optimized for every turbine application to achieve

optimum efficiency and pressure drop.

FEATURES

- DCL design support to assist with catalyst optimization.

- Thin walled metal cell structure available in a variety of cell

densities for optimum emission performance and pressure drop.

- Catalyst coating and PGM usage is optimized based on price and

efficiency targets.

- Flexible manufacturing allows parts to be produced in a variety of

substrate shapes, making the parts ideal for retrofit or fitting into

unique exhaust duct footprints.

- Premium grade metallic substrate structure capable of high temperature

operation.

- Catalyst elements available in un-brazed monoliths for reduced cost and

solid brazed monoliths for long term durability in high turbulent zones.